Thread Engagement Chart

Thread engagement is a crucial metric while selecting fasteners, as it directly affects the strength and stability of the connection. Understanding how to calculate and choose the appropriate thread engagement can help ensure the strength and effectiveness of the fastener in any given application. A thread engagement chart can guide the recommended thread engagement for different fasteners and materials.

Table of contents

Explore Tameson's selection of thread cutting tools

What is thread engagement?

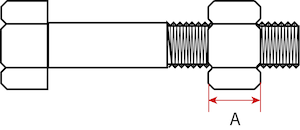

Thread engagement (Figure 2 labeled A) is the available mating amount available between two threaded portions of a threaded assembly. It measures how deeply a bolt or screw gets seated into a threaded hole. Two factors define thread engagement:

- Length of thread engagement: The interaction length between the fastener and the nut (i.e., a nut or any other mating material for the screw) yields the thread engagement. For example, a conventional thread-forming screw applied in 12 mm of material will tend to have more thread engagement length than the same screw put in 7 mm.

- Percentage of thread engagement: The percentage of thread engagement depends on the size of the mating hole compared to the fastener and the screw thread’s height that is engaged. For example, a #10-24 thread-forming screw will have approximately 80% thread engagement in a hole of 0.16 inches (4.06 mm) while around 70% thread engagement in a .17 inch (4.32 mm) hole.

It is crucial to select an optimum thread engagement length. If the thread engagement length is too short, the bolted joint will not be strong enough. And if it is too long, the overall cost increases, and the torque needed to drive the screw tends to be high. Excessive thread engagement may result in higher tensile strength per joint. The tensile strength of a material is the force required to pull something until it cuts off or the capacity of that particular material to withstand that load. Therefore, using a bolt longer than needed results in the wastage of excess material. Also, if the bolt length engaged in a nut member is insufficient, the bolt has a higher chance of stripping out before achieving its full tensile strength capacity. Read our thread compatibility article for more details on the compatibility between various thread standards.

Figure 2: Thread engagement length

Read our thread design article for more details on thread design parameters.

Recommended thread engagement

While making a connection, the bolted joints should be designed so that the screw breaks before the threads strip. For components with tapped holes, the length of engagement (the number of threads engaged between the tapped hole and the screw) should be adjusted to favor this criterion. Table 1 summarizes the general rule of thumb for thread engagement distance calculation.

Table 1: General rule of thumb for thread engagement distance calculation

| Material | Minimum thread engagement distance |

| Steel | 1.0 to 1.5 x base diameter of the screw or bolt |

| Cast iron, brass | 1.5 to 2.0 x base diameter of the screw or bolt |

| Aluminum | 2.0 to 2.5 x base diameter of the screw or bolt |

| Soft materials (like plastic) | The minimum thread engagement distance will be higher and require trials to establish the optimum joint strength. |

Perform the following steps to calculate the thread engagement:

- Determine the thread pitch using a pitch gauge. The pitch is the distance between adjacent threads, typically measured in millimeters.

- Measure the length of the threaded portion of the fastener.

Then, thread engagement = (length of thread on the fastener) - (pitch ✕ number of threads on the fastener)

Example

If a fastener has a thread length of 2 inches (50.8 mm) and a pitch of 0.25 inches (6.35 mm), and there are 6 threads on the fastener, the thread engagement can be calculated as:

Thread engagement = 2 inches - (0.25 inches ✕ 6) = 0.5 inches (12.7 mm)

Thread engagement chart

A thread engagement chart is a useful tool for determining the appropriate thread engagement for a given fastener and application. These charts typically provide a range of recommended thread engagement percentages for different fastener types and materials, as well as the corresponding lengths of thread engagement in inches or millimeters (Tables 2-3).

Table 2: An example of a thread engagement chart

|

Thread size |

Nominal diameter (inch) |

Nut Material: Low carbon steel |

Nut material: Nodular iron |

||||

| Grade 2 (in) | Grade 5 (in) | Grade 8 (in) | Grade 2 (in) | Grade 5 (in) | Grade 8 (in) | ||

| ¼ - 20 | 0.25 | 0.14 | 0.23 | 0.29 | 0.13 | 0.21 | 0.27 |

| 5/16 - 18 | 0.31 | 0.19 | 0.31 | 0.38 | 0.17 | 0.28 | 0.35 |

| ⅜ - 16 | 0.375 | 0.23 | 0.38 | 0.47 | 0.21 | 0.35 | 0.43 |

| 7/16 - 14 | 0.438 | 0.27 | 0.44 | 0.56 | 0.25 | 0.41 | 0.51 |

| ½ - 13 | 0.5 | 0.32 | 0.52 | 0.65 | 0.29 | 0.47 | 0.59 |

| ⅝ - 11 | 0.62 | 0.41 | 0.66 | 0.83 | 0.37 | 0.61 | 0.76 |

| ¾ - 10 | 0.7 | 0.5 | 0.82 | 1.02 | 0.46 | 0.75 | 0.93 |

Table 3: NPT standard thread engagement chart

| Nominal size (Inner diameter) | Actual outer diameter | Threads per inch | Length of engagement |

| 1/16 | 0.3125 | 27 | 0.16 |

| 1/8 | 0.405 | 27 | 0.18 |

| 1/4 | 0.54 | 18 | 0.2 |

| 3/8 | 0.675 | 18 | 0.24 |

| 1/2 | 0.84 | 14 | 0.32 |

| 3/4 | 1.05 | 14 | 0.34 |

| 1 | 1.315 | 11.5 | 0.4 |

| 1 ¼ | 1.66 | 11.5 | 0.42 |

| 1 ½ | 1.9 | 11.5 | 0.42 |

| 2 | 2.375 | 11.5 | 0.436 |

| 2 ½ | 2.875 | 8 | 0.682 |

| 3 | 3.5 | 8 | 0.766 |

| 3 ½ | 4 | 8 | 0.821 |

| 4 | 4.5 | 8 | 0.844 |

| 5 | 5.563 | 8 | 0.937 |

FAQs

What is thread engagement?

Thread engagement refers to the amount of thread that is in contact with each other when two threads are joined together. It is a measure of how securely a fastener is held in place.

What is the typical thread engagement percentage?

Typical designs in engineering use a thread engagement of 75% and a length of engagement of 1.5 times the diameter of the screw.