Hacksaw Blade Selection

Figure 1: Hacksaw cutting through a steel pipe.

To ensure a hacksaw blade functions properly, it is important to select the right blade for the application. It helps ensure a better cutting experience and keeps the blade in good condition, expanding its longevity. The primary factors to consider when selecting a blade are the material of the blade and object to cut, the blade’s TPI (tooth-per-inch), and the desired cut smoothness.

Table of contents

View our online selection of hacksaws!

Hacksaw design and function

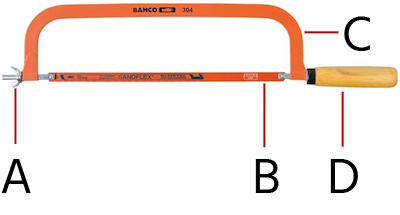

The four key components of many hacksaws are the handle (Figure 2 labeled D), blade (Figure 2 labeled B), frame (Figure 2 labeled C), and wingnut or tensioning knob (Figure 2 labeled A).

- Handle: Most hacksaw handles are pistol type, as seen in Figure 2, or straight type.

- Frame: Frames can be adjustable to fit different blade lengths or fixed to fit only one blade length.

- Blade: The blade tightly fixes to the frame, making it strong enough to cut through metal. The blade’s teeth face towards the front of the saw.

- Wingnut/Tensioning Knob: Some hacksaw designs use a wingnut whereas other designs use a knob. Either way, the purpose of this device is to put tension on the blade to make it strong enough for cutting, or loosen the tension on the hacksaw.

Figure 2: A typical hacksaw design: wingnut (A), blade (B), frame (C), and handle (D).

Hacksaw function

The difference between a normal saw and a hacksaw is that a hacksaw’s blade has higher TPI, making it cut more efficiently. Therefore, hacksaws work best with harder materials like metals and plastics such as PVC, PEX, and ABS. However, hardness is not the only factor to consider.

Hacksaws are a budget-friendly option for cutting through thick metals, but are not the most efficient. Hacksaws are not for rapid cutting as the excess heat can bind the teeth. Therefore, a great deal of time is necessary to use a hacksaw to cut through thick metal. A circular saw is more suitable for cutting through thick metals if available.

Hacksaw TPI

As seen in Figure 3, hacksaw blade teeth are forward facing and work like scoops to move material away from what is being cut. Typically, hacksaw teeth have 8, 14, 18, 24, or 32 TPI (tooth-per-inch).

Lower TPI blades cut faster because they have larger teeth, which move more material away. However, these cuts are also coarser. High TPI blades are suitable for cleaner cuts because the small teeth slowly move material away. The following details some common applications for the range of TPI.

- Course grade: 14-18 TPI. Suitable for cutting mild steel, brass, copper, and aluminum.

- Medium grade: 20-24 TPI. Suitable for cast iron, high carbon steel, brass, and aluminum.

- Fine grade: 24-30 TPI. Suitable for thin metal sheets.

- Superfine grade: 30-32 TPI. Suitable for solid metals and thin sheets.

Figure 3: Close up on a hacksaw blade’s teeth above a cut steel screw.

Hacksaw blade teeth positioning

The positioning of the blade’s teeth impacts how the blade cuts and which applications its suitable for. There are three blade categorizations based on how the teeth are positioned: raker, wavy, and regular.

- Raker: The teeth are in sets of three. This blade is ideal for thick iron piping.

- Wavy: The teeth are positioned from left to right. This blade is ideal for cutting thin but hard metal sheets.

- Regular: The teeth alternate between left and right, but they also touch each other. This blade is ideal for cutting soft materials like aluminum or tin.

Hacksaw blade materials

Hacksaw blades are typically constructed from three types of metal: carbon steel, high speed steel, bimetal material, or special materials like tungsten carbide..

- Carbon steel: A blade composed entirely of carbon steel, teeth included, is suitable for DIY and non-demanding jobs. The flexibility of carbon steel is suitable for work that cannot be clamped down or is in an awkward location. These blades wear faster than high speed steel, but are also less expensive.

- High speed steel: High speed steel has a higher temperature rating than carbon steel, and therefore is suitable for cutting through stronger material since the blade will wear more slowly.

- Bimetal: Bimetal blades combine the best attributes of carbon steel and high speed steel. These blades use carbon steel for the blade’s body and high speed steel for the teeth. This gives the blade flexibility and durability. These blades are considerably more expensive than carbon steel and high speed steel blades.

- Tungsten carbide: A tungsten carbide hacksaw blade typically has a carbon steel body, high speed steel teeth, and tungsten carbide content throughout the teeth. These blades can cut forward and backward. They are suitable for cutting through ceramics, glass, marble, and other hard materials.

Read our hacksaw blade replacement article for more information on how to replace a hacksaw blade.

Hacksaw applications

Cutting metal is likely the hacksaw’s best known application, however these blades are also suitable for cutting through plastic, and wood and stone in special circumstances. This section briefly describes these applications and then focuses primarily on cutting metal.

Wood

Hacksaw blades for wood should have the smallest TPI available; a carbon steel 8 TPI blade is a good choice because it works well with softer material and has more space between teeth, preventing excess sawdust accumulation. Sawdust accumulation between teeth can cause the blade to lose its efficiency. Less efficient blades require more effort to cut the material, which produces excess heat and quickly wears the blade. When using hacksaw blades with TPI greater than 14, a user must periodically knock the sawdust free from the blade.

Even with low TPI, however, hacksaws are not ideal for cutting wood because the blades tend to bend a lot while cutting, risking breakage. A better choice is a typical handsaw, as seen in Figure 4. Hand saws have 7-10 TPI, thicker blades, and cut forward and backward, so are less likely to get stuck in the wood.

Figure 4: A hand saw cutting wood.

Stone

Tungsten carbide hacksaws can cut through stone when there is a need for a precise cut. Similar to thick metals, hacksaws are not the best choice for making thick cuts on stone. A circular saw with a diamond blade is much more suitable for the task.

Plastics

Plumbers often use hacksaws to cut through plastic piping. A hacksaw blade for PVC, PEX, or ABS should have a minimum of 24 TPI to make the work efficient.

Hacksaws leave rough edges and burrs on plastic piping that must be smoothed and deburred before the pipe is usable. 32 TPI hacksaw blades cut slower but cleaner. The cleaner the cut, the less cleanup is required afterward.

Metals

Hacksaws are ideal for cutting metal tubing or sheets of metal thinner than 6 mm. Typical applications for hacksaws are stainless steel, aluminum, copper, carbon fiber, and ferrous metals.

- Stainless steel: Stainless steel is hard to cut, so using a hacksaw will leave behind rough edges and burrs. Therefore, a 32 TPI hacksaw blade is the best choice to reduce the coarseness of the cut as much as possible. This method, however, will also take the most amount of time.

- Aluminum: As aluminum is soft, a hacksaw is suitable for cutting solid aluminum tubing. A hacksaw blade for solid aluminum bar stocks or plates should have the lowest TPI available, typically 8 TPI, but 14 TPI is also suitable. This increases the speed of the cutting and reduces the amount of aluminum shavings that clog the teeth. For thin sheets of aluminum or hollow aluminum tubing, choose a 32 TPI blade for a clean cut.

- Copper: A hacksaw blade for copper pipe should be 32 TPI for the cleanest cut possible. Copper is soft, and no matter how fine the blade is, ridges and burrs will be left behind after the cut. Cutting copper pipe is simple when the pipe is independent of a piping system. However, a pipe in a system may be difficult to reach and unlikely to brace. Therefore, the cut will not be clean. A pipe cutter is ideal for in situ copper pipes.

- Carbon fiber: Carbon fiber is commonly cut when assembling or repairing bicycles, for the steering handle or seat post, for example. A hacksaw blade for carbon fiber can have 24 TPI, but cuts made by 32 TPI blades will require less attention after the cut.

- Ferrous metals: When cutting ferrous metals, such as iron, ensure the blade is bimetal with high speed steel teeth. Opt for a blade with 18, 24, or 32 TPI. The smaller the TPI, the faster the cutting work will go.

FAQs

What material is a hacksaw blade made from?

Hacksaw blades are typically made from carbon steel, bimetal material, and high speed steel. A good bimetal combination is a flexible carbon steel body with high speed steel teeth.

Will a hacksaw cut aluminum?

A hacksaw can cut through thick aluminum bar stock and thin aluminum tubing and sheets. For thinner aluminum, use a 32 TPI hacksaw blade. For thicker aluminum, use an 8 or 14 TPI hacksaw blade.